US Innovation in Robotics: Transforming Industries from Manufacturing to Healthcare

US robotics innovation is profoundly transforming diverse sectors, from enhancing efficiency in manufacturing to delivering advanced care in healthcare, driving unprecedented technological advancement and redefining industry landscapes.

The Dawn of a New Industrial Revolution: US Robotics Innovation

The United States stands at the forefront of a technological revolution, where US robotics innovation is not just a concept but a tangible force reshaping industries. From the precision of manufacturing floors to the critical care environments of hospitals, robots are no longer confined to science fiction. They are integral to solving complex challenges, enhancing productivity, and improving human lives. This pervasive integration marks a new chapter in industrial evolution, promising efficiencies and capabilities previously unimaginable.

Manufacturing Reimagined: Precision, Efficiency, and Safety

The manufacturing sector in the US has long been a bedrock of the nation’s economy. However, facing global competition and evolving demands, it has embraced robotics as a critical catalyst for transformation. Robots are not merely replacing human labor but are augmenting it, creating smarter, safer, and more efficient production lines.

This integration goes beyond simple automation. Modern manufacturing robots are equipped with advanced sensors, artificial intelligence, and machine learning capabilities, allowing them to perform intricate tasks with unparalleled accuracy. They can handle repetitive, dangerous, or ergonomically challenging jobs, freeing human workers to focus on more complex problem-solving, quality control, and strategic planning.

Collaborative Robots (Cobots) on the Rise

One of the most significant advancements in manufacturing robotics is the emergence of collaborative robots, or cobots. These robots are designed to work safely alongside humans, sharing the same workspace without the need for extensive safety caging. Their intuitive programming and adaptable nature make them ideal for a variety of tasks.

- Enhanced Flexibility: Cobots can be easily reprogrammed and redeployed for different tasks, offering agility in production.

- Improved Ergonomics: They can handle heavy lifting and repetitive motions, reducing strain and injury risk for human workers.

- Increased Throughput: By automating mundane steps, cobots help accelerate production cycles and boost output.

- Consistent Quality: Their precision ensures uniform product quality, minimizing defects and waste.

The adoption of cobots signifies a shift towards a more integrated human-robot workforce, where each entity contributes its unique strengths to optimize the manufacturing process. This synergy is crucial for maintaining competitiveness and fostering innovation within the US manufacturing landscape.

Advanced Automation in Production Lines

Beyond cobots, advanced automation systems are streamlining entire production lines. From material handling to final assembly and quality inspection, robots are performing tasks with speed and accuracy that surpass human capabilities. This has led to a significant reduction in operational costs and an increase in overall productivity.

For instance, in the automotive industry, robotic arms precisely weld, paint, and assemble vehicle components, ensuring high standards of quality and consistency. In electronics manufacturing, micro-robots handle delicate components with extreme precision, critical for the production of advanced devices. These applications underscore the profound impact of US robotics innovation on industrial efficiency.

Healthcare Revolutionized: From Surgery to Patient Care

The healthcare sector is another domain profoundly impacted by US robotics innovation. Robots are transforming patient care, surgical procedures, diagnostics, and pharmaceutical logistics. Their ability to perform with precision, tirelessly, and in sterile environments makes them invaluable assets in medical settings.

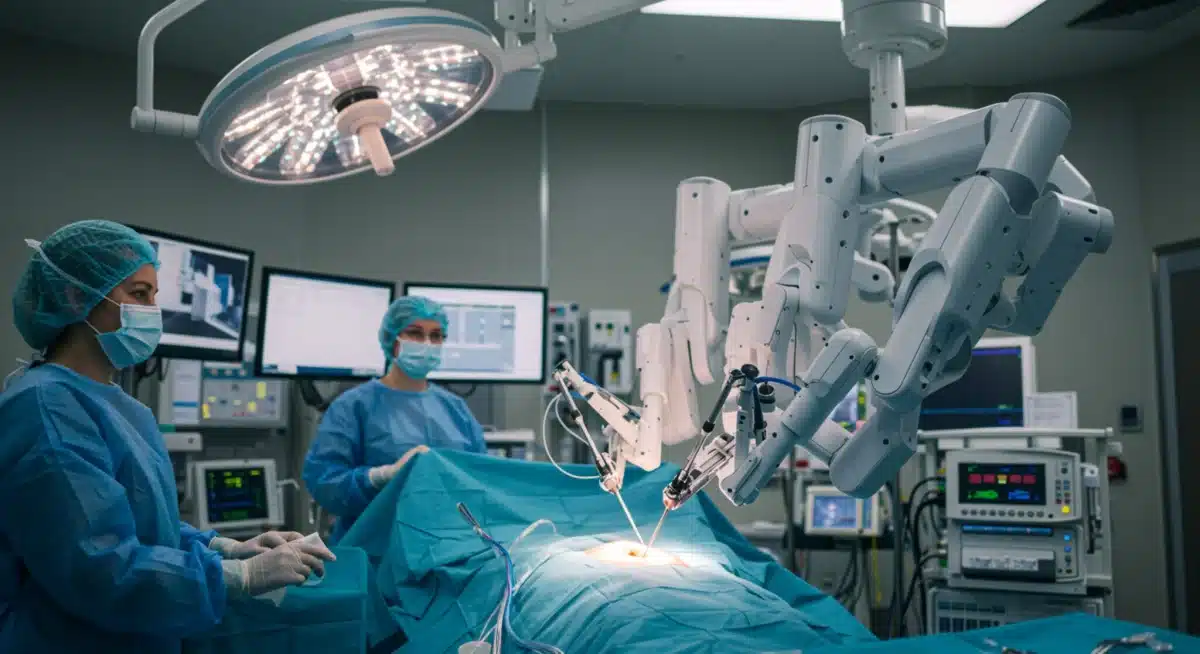

In operating rooms, surgical robots are enabling minimally invasive procedures, leading to smaller incisions, reduced blood loss, faster recovery times, and decreased post-operative pain for patients. These systems enhance surgeons’ capabilities, providing greater dexterity and visualization, especially in complex surgeries. This technological leap represents a significant improvement in patient outcomes and healthcare efficiency.

Surgical Robotics: A New Era of Precision Medicine

Surgical robots, such as the da Vinci Surgical System, have become commonplace in hospitals across the US. These systems allow surgeons to control robotic arms equipped with tiny instruments and high-definition 3D cameras, translating their hand movements into precise micro-movements inside the patient’s body. This level of control is particularly beneficial for intricate procedures in urology, gynecology, cardiology, and general surgery.

- Enhanced Visualization: 3D high-definition cameras provide a magnified, immersive view of the surgical site.

- Increased Dexterity: Robotic wrists can rotate far more than human hands, allowing for greater maneuverability in tight spaces.

- Reduced Tremor: The robotic system filters out natural human tremors, ensuring steady and precise movements.

- Improved Patient Outcomes: Minimally invasive approaches lead to quicker recovery and fewer complications.

The continuous development in surgical robotics promises even more advanced capabilities, including autonomous surgical tasks guided by AI, further pushing the boundaries of what’s medically possible.

Robots in Patient Support and Logistics

Beyond surgery, robots are playing increasingly vital roles in patient support and hospital logistics. Service robots assist with tasks like delivering medications, meals, and linens, reducing the workload on nursing staff and allowing them to focus more on direct patient care. Disinfection robots use UV light to sterilize hospital rooms, significantly reducing the risk of healthcare-associated infections.

Furthermore, exoskeletons and rehabilitation robots are aiding patients in physical therapy, helping them regain mobility and strength after injuries or strokes. These devices provide personalized, intensive therapy that can accelerate recovery and improve long-term functional outcomes. The application of robotics in these areas highlights a holistic approach to improving healthcare delivery and patient well-being.

Logistics and Supply Chain Automation: The Backbone of Modern Commerce

The efficiency of logistics and supply chains is paramount in today’s global economy. US robotics innovation is at the forefront of automating these complex networks, ensuring faster, more accurate, and cost-effective movement of goods. From vast e-commerce warehouses to intricate distribution centers, robots are optimizing every step of the supply chain.

Autonomous mobile robots (AMRs) and automated guided vehicles (AGVs) are revolutionizing warehouse operations. These robots can navigate dynamic environments, retrieve items, transport them to packing stations, and even assist with inventory management. This automation significantly reduces the time and labor required for order fulfillment, especially critical during peak seasons and for same-day delivery demands.

Warehouse Efficiency with Robotics

In large-scale warehouses, the sheer volume of goods and the speed required for processing make manual operations increasingly challenging. Robots provide a scalable solution, capable of working 24/7 without fatigue. They excel at repetitive tasks, such as picking, packing, and sorting, which often represent bottlenecks in traditional logistics systems.

- Faster Order Fulfillment: Robots can locate and retrieve items much quicker than human operators.

- Optimized Space Utilization: Advanced algorithms allow robots to navigate and store items in dense configurations, maximizing warehouse space.

- Reduced Errors: Automated systems minimize human error in picking and packing, leading to higher order accuracy.

- Improved Safety: Robots can handle heavy loads and operate in environments that might be hazardous for humans.

The integration of robotics in logistics is not just about speed; it’s about creating a resilient and responsive supply chain capable of meeting the dynamic demands of consumers and businesses. This technological shift ensures that goods move seamlessly from production to consumption, bolstering economic activity.

Innovations in Last-Mile Delivery

The final leg of the supply chain, known as last-mile delivery, is often the most challenging and costly. Here, too, robotics is offering innovative solutions. Drone delivery and autonomous ground vehicles are being piloted and deployed in various capacities to deliver packages directly to consumers. While still in early stages of widespread adoption, these technologies promise to revolutionize urban logistics, reducing traffic congestion and environmental impact.

These robotic delivery systems are designed to be efficient and secure, offering a glimpse into a future where packages arrive faster and with greater convenience. The continuous investment in R&D in this area signifies the US commitment to pushing the boundaries of logistical efficiency through robotics.

Agriculture and Food Processing: Harvesting the Future

Beyond manufacturing and healthcare, US robotics innovation is making significant inroads into agriculture and food processing, sectors vital for national well-being. These industries face challenges such as labor shortages, increasing demand for food, and the need for sustainable practices. Robotics offers solutions that address these issues, enhancing productivity and efficiency from farm to table.

In agriculture, robots are performing tasks like precision planting, automated harvesting, crop monitoring, and pest control. These robotic systems can operate with a level of precision that minimizes waste, optimizes resource use (water, fertilizers), and improves crop yields. This is particularly important for specialty crops that require delicate handling or precise timing for harvesting.

Robotics in Precision Agriculture

Precision agriculture leverages robotics to gather detailed data about soil conditions, plant health, and environmental factors. Autonomous tractors and drones equipped with sensors and cameras can scan vast fields, identifying areas that need specific attention. This data-driven approach allows farmers to apply resources only where and when needed, leading to more sustainable farming practices and reduced operational costs.

Robotic harvesters are also transforming the way fruits and vegetables are picked. These robots can identify ripe produce using computer vision and carefully pick it without causing damage, addressing the labor-intensive nature of harvesting and ensuring consistent quality. This automation is crucial for maintaining a stable food supply chain.

Automating Food Processing and Packaging

In food processing plants, robots are handling tasks that require high levels of hygiene, speed, and consistency. From sorting and cutting to packaging and quality inspection, robotic systems minimize human contact with food products, reducing contamination risks and improving food safety. Their ability to work in cold or harsh environments also makes them ideal for tasks that are uncomfortable or hazardous for human workers.

For example, in meat packing plants, robotic arms can precisely cut and debone products, improving efficiency and reducing the risk of injury to workers. In bakeries, robots can handle delicate pastries, ensuring consistent quality and presentation. These applications underscore the versatility of robotics in ensuring the safety and efficiency of our food supply.

The Economic and Societal Impact of Robotics

The widespread adoption of robots across various industries in the US is not without significant economic and societal implications. While concerns about job displacement often arise, the reality is more nuanced. Robotics is creating new job categories, requiring different skill sets, and leading to a re-evaluation of the human role in the workforce.

Economically, robotics drives productivity growth, increases competitiveness, and fosters innovation. Companies that adopt robotics often experience higher output, lower operational costs, and improved product quality, which can translate into greater market share and economic expansion. This investment in automation positions the US as a leader in advanced technological development.

Workforce Transformation and Skill Development

The integration of robots necessitates a transformation in the workforce. There is a growing demand for skilled professionals who can design, program, maintain, and troubleshoot robotic systems. This shift requires significant investment in education and training programs to equip the current and future workforce with the necessary capabilities. Initiatives in STEM education, vocational training, and reskilling programs are critical to ensure that workers can adapt to the evolving job market.

- New Job Creation: Roles for robot technicians, automation engineers, and data scientists are emerging.

- Enhanced Human Roles: Workers can transition to supervisory, analytical, or creative tasks that leverage uniquely human skills.

- Increased Safety: Robots take over dangerous jobs, improving overall workplace safety.

- Economic Growth: Increased productivity and innovation contribute to national economic prosperity.

This transformation is an opportunity to elevate human work, focusing on tasks that require critical thinking, creativity, and interpersonal skills, while robots handle the repetitive and physically demanding aspects.

Ethical Considerations and Future Development

As robotics technology advances, ethical considerations become increasingly important. Issues such as data privacy, algorithmic bias, and the responsible deployment of autonomous systems require careful consideration. Policymakers, industry leaders, and researchers are actively engaged in developing frameworks and guidelines to ensure that robotics innovation benefits society responsibly and equitably.

The future of robotics in the US is bright, with ongoing research and development in areas like artificial intelligence, machine learning, and advanced materials promising even more sophisticated and versatile robots. The continuous push for innovation will further integrate robots into daily life, transforming more industries and enhancing human capabilities in unprecedented ways.

Challenges and the Path Forward for US Robotics

While US robotics innovation has achieved remarkable progress, the path forward is not without its challenges. Overcoming these hurdles is crucial for sustaining leadership in this rapidly evolving field. Key challenges include the high initial investment costs for advanced robotic systems, the need for a highly skilled workforce, and the complexities of integrating diverse robotic technologies into existing infrastructures.

Another significant challenge lies in ensuring that the benefits of robotics are broadly distributed across society, preventing a widening of economic disparities. Addressing these issues requires a concerted effort from government, industry, and academia to foster an environment conducive to continued innovation and equitable adoption.

Overcoming Adoption Barriers

For many small and medium-sized enterprises (SMEs), the initial capital outlay for robotic systems can be prohibitive. Government incentives, subsidies, and financing programs can play a vital role in lowering these barriers, enabling more businesses to adopt automation. Furthermore, developing more modular, scalable, and affordable robotic solutions can make the technology accessible to a wider range of users.

The complexity of integrating robots with legacy systems also poses a challenge. Standardized protocols and open-source platforms can facilitate smoother integration, reducing the technical expertise required for deployment. Simplifying user interfaces and programming tools will also empower more businesses to leverage robotics without needing extensive specialized knowledge.

Fostering a Robust Robotics Ecosystem

Building a robust robotics ecosystem requires continuous investment in research and development, supported by strong public-private partnerships. Funding for university research, startup incubators, and innovation hubs is critical for generating new breakthroughs and translating them into practical applications. Collaboration between industry and academia ensures that research efforts are aligned with real-world needs and market demands.

Moreover, fostering a culture of innovation and entrepreneurship is essential. Encouraging interdisciplinary collaboration, promoting STEM education from an early age, and supporting lifelong learning initiatives will cultivate the talent pipeline necessary for sustained growth in the robotics sector. The US commitment to these areas will determine its long-term success in robotics innovation.

| Key Aspect | Brief Description |

|---|---|

| Manufacturing Transformation | Robots enhance precision, efficiency, and safety in production, creating smarter factories. |

| Healthcare Advancements | Surgical robots enable minimally invasive procedures and improve patient care outcomes. |

| Logistics & Supply Chain | Autonomous robots optimize warehousing, order fulfillment, and last-mile delivery. |

| Societal Impact | Robotics creates new job categories and drives economic growth, requiring workforce adaptation. |

Frequently Asked Questions About US Robotics Innovation

US robotics innovation is revolutionizing manufacturing by enhancing precision, efficiency, and safety. Collaborative robots work alongside humans, while advanced automation streamlines production lines, reduces costs, and improves product quality across various sectors like automotive and electronics.

In US healthcare, robots are crucial for surgical precision, enabling minimally invasive procedures with faster patient recovery. They also assist in patient support, logistics, and disinfection, allowing medical staff to focus more on direct patient care and improve overall hospital efficiency and safety.

While robots automate some tasks, in the US they are primarily transforming existing jobs and creating new ones. They take on repetitive or dangerous roles, allowing humans to focus on higher-value tasks requiring creativity and critical thinking. This shift necessitates workforce reskilling and education.

Robotics significantly boosts US supply chain and logistics by automating warehousing, order fulfillment, and last-mile delivery. Autonomous mobile robots optimize inventory management and package movement, leading to faster processing, reduced errors, and more resilient distribution networks, especially for e-commerce.

The future of US robotics innovation looks promising, with continued advancements expected in AI, machine learning, and human-robot interaction. Further integration into daily life, addressing ethical considerations, and fostering a skilled workforce are key to maintaining US leadership and expanding robotic applications across more industries.

Conclusion

The landscape of American industry is being profoundly reshaped by the relentless march of US robotics innovation. From the sophisticated automation of manufacturing processes that yield higher quality and efficiency, to the life-saving precision of robots in healthcare, and the optimized flow of goods in logistics, robots are proving to be indispensable. This technological evolution is not merely about machines performing tasks; it’s about augmenting human capabilities, creating safer work environments, and driving economic growth. As the United States continues to invest in research, development, and workforce adaptation, the transformative power of robotics will only expand, promising a future where technology and human ingenuity collaborate to solve some of the world’s most pressing challenges. The journey of integrating robotics is complex, yet it holds the key to a more productive, healthier, and technologically advanced society.