Nanotechnology Advancements: US Manufacturing’s Future

Nanotechnology advancements are fundamentally transforming US manufacturing and materials science, enabling unprecedented precision, efficiency, and the creation of novel products across diverse industries, securing a competitive edge.

Have you ever wondered how the smallest innovations can create the biggest impact? The world of nanotechnology US manufacturing is precisely that — a realm where manipulating matter at the atomic and molecular scale is revolutionizing industries and shaping the future of materials science in the United States. This profound shift promises not just incremental improvements, but entirely new paradigms in how products are designed, produced, and perform.

The implications of nanotechnology for US manufacturing are vast, touching everything from aerospace and automotive to medicine and consumer electronics. By engineering materials with enhanced properties like strength, conductivity, and reactivity, nanotechnology is paving the way for lighter, stronger, smarter, and more sustainable products. This deep dive will explore the critical advancements, their current impact, future potential, and the challenges that lie ahead in harnessing this powerful technology for American industry.

The Dawn of Nanoscale Engineering in Manufacturing

The journey into nanotechnology began with theoretical concepts, but it has rapidly evolved into practical applications that are redefining what’s possible in manufacturing. At its core, nanoscale engineering involves working with materials measured in nanometers—one billionth of a meter. This allows for unparalleled control over material properties, opening doors to innovations far beyond the reach of traditional manufacturing methods.

In the US, this field is not merely an academic pursuit; it’s a strategic imperative. The ability to manipulate matter at such a fundamental level provides a competitive advantage, fostering the development of proprietary technologies and high-value products. This strategic focus is crucial for maintaining leadership in a globalized economy.

Precision and Performance

One of the most immediate benefits of nanotechnology in manufacturing is the ability to create materials and devices with extraordinary precision and enhanced performance characteristics. Traditional manufacturing often operates at the macro or micro scale, limiting the ultimate properties that can be achieved. Nanoscale engineering overcomes these limitations, enabling materials with superior strength-to-weight ratios, improved electrical conductivity, and novel optical properties.

- Enhanced Material Properties: Nanoparticles and nanofibers can be incorporated into existing materials to dramatically improve their strength, durability, and resilience, such as in lightweight composites for aircraft.

- Miniaturization of Devices: Shrinking components to the nanoscale allows for the creation of smaller, more powerful electronic devices and sensors, critical for advancements in IoT and medical implants.

- Surface Engineering: Nanocoatings can bestow surfaces with properties like self-cleaning, anti-corrosion, or extreme hardness, extending product lifespan and reducing maintenance needs.

These capabilities are not just theoretical; they are actively being integrated into various manufacturing processes across the United States. From semiconductor fabrication to the production of advanced textiles, the impact of nanoscale engineering is becoming increasingly tangible, driving both product innovation and process efficiency.

The precise control offered by nanotechnology allows manufacturers to tailor materials for specific applications, achieving performance levels previously unimaginable. This level of customization and enhancement is a key driver for the adoption of nanotechnology in US industrial sectors, leading to a new generation of high-performing products.

Revolutionizing Materials Science: A New Era of Composites and Coatings

Materials science is arguably where nanotechnology’s influence is most profound. By understanding and controlling atomic and molecular structures, scientists and engineers are developing entirely new classes of materials with tailored properties. This revolution is particularly evident in the creation of advanced composites and smart coatings, which are setting new benchmarks for performance and functionality.

The US is at the forefront of this materials revolution, with significant investments in research and development aimed at discovering and commercializing novel nanomaterials. These advancements are crucial for sectors demanding extreme conditions, such as defense, energy, and space exploration, but also for everyday consumer goods.

Advanced Composite Materials

Nanocomposites, which combine conventional materials with nanoscale fillers, offer unprecedented improvements in mechanical strength, thermal stability, and electrical conductivity. These materials are lighter yet stronger than their traditional counterparts, making them ideal for applications where weight reduction and structural integrity are paramount.

- Aerospace Industry: Lighter aircraft components lead to significant fuel savings and reduced emissions, enhancing both economic viability and environmental sustainability.

- Automotive Sector: Stronger, lighter vehicle parts improve fuel efficiency and enhance passenger safety, driving innovation in electric vehicle design.

- Construction: Nanocomposites can create more durable and resilient building materials, capable of withstanding extreme weather conditions and reducing maintenance cycles.

The integration of these advanced composites is transforming manufacturing processes, requiring new tooling and assembly techniques. US manufacturers are investing heavily in adapting their facilities and workforce to leverage these materials effectively, ensuring they remain competitive globally.

Smart Coatings and Surfaces

Nanotechnology enables the development of coatings that are not just protective, but also functional. These ‘smart’ coatings can respond to environmental stimuli, self-heal, or provide specific antimicrobial properties. This has massive implications for longevity, hygiene, and efficiency across various products and infrastructure.

Imagine surfaces that repel dirt and water, or medical implants that actively prevent bacterial growth. These are not futuristic fantasies but current applications being developed and deployed thanks to nanoscale engineering. The economic benefits are substantial, reducing the need for harsh cleaning agents, extending product lifespans, and improving public health outcomes.

The continuous evolution of smart coatings demonstrates the dynamic nature of nanotechnology, constantly pushing the boundaries of what materials can achieve. This area of materials science is critical for US manufacturing to produce high-value goods that offer superior performance and unique advantages in the marketplace.

Impact on US Manufacturing Sectors: From Aerospace to Healthcare

The transformative power of nanotechnology is not confined to a single industry; it permeates various sectors of US manufacturing, each experiencing unique benefits and challenges. From the precision demands of aerospace to the life-saving innovations in healthcare, nanotechnology is a pervasive force for change.

The diverse applications underscore the versatility of nanoscale engineering and its potential to revitalize and strengthen the American industrial base. By fostering innovation across these sectors, the US aims to secure its position as a global leader in advanced manufacturing.

Aerospace and Defense

In aerospace, nanotechnology is paramount for creating lighter, stronger, and more fuel-efficient aircraft. Nanocomposites reduce structural weight without compromising strength, which translates directly into reduced fuel consumption and increased payload capacity. For defense, these materials offer enhanced ballistic protection and stealth capabilities, critical for national security.

The precision afforded by nanoscale manufacturing also enables highly sophisticated sensors and electronic components that are more resilient to extreme conditions, ensuring reliability in critical applications. This continuous push for superior performance is a hallmark of nanotechnology’s integration into these demanding sectors.

Automotive Industry

The automotive sector benefits from nanotechnology through the development of lighter vehicles, leading to improved fuel economy and reduced emissions. Nanocoatings enhance scratch resistance, corrosion protection, and even contribute to self-cleaning surfaces. Furthermore, advancements in battery technology, driven by nanomaterials, are crucial for the widespread adoption and efficiency of electric vehicles.

These innovations are not just about performance; they also address environmental concerns and consumer demands for more durable and sustainable products. The US automotive industry is actively exploring and implementing these nanotechnologies to stay competitive and meet future regulatory standards.

Healthcare and Biomedical Devices

Perhaps one of the most exciting areas, nanotechnology is revolutionizing healthcare. Nanomaterials are used in targeted drug delivery systems, allowing medications to reach specific cells with greater efficiency and fewer side effects. Nanoscale sensors enable earlier and more accurate disease detection, from cancer to infectious diseases.

- Improved Diagnostics: Nanobiosensors can detect disease biomarkers at extremely low concentrations, leading to earlier diagnosis and intervention.

- Advanced Therapies: Nanoparticles can encapsulate drugs, delivering them precisely to tumor cells or infected tissues, minimizing systemic toxicity.

- Biocompatible Implants: Nanocoatings on medical implants reduce the risk of rejection and infection, improving patient outcomes and longevity of devices.

The development of advanced medical devices and diagnostic tools powered by nanotechnology is a testament to its profound impact on human health, driving significant investment and research in the US biomedical sector.

Across these diverse manufacturing sectors, nanotechnology is not just an incremental improvement; it’s a foundational shift that enables entirely new product capabilities and manufacturing efficiencies. The strategic adoption of these technologies is vital for US industries to remain innovative and globally competitive.

Challenges and Opportunities in Nanotechnology Adoption

While the promise of nanotechnology is immense, its widespread adoption in US manufacturing is not without challenges. These include high research and development costs, the need for specialized infrastructure, workforce training, and navigating regulatory complexities. However, overcoming these hurdles presents significant opportunities for economic growth and technological leadership.

Addressing these challenges proactively is crucial for the US to fully capitalize on the potential of nanoscale engineering and ensure a responsible and sustainable integration into its industrial landscape.

Economic and Infrastructural Hurdles

The initial investment required for nanotechnology research, specialized equipment, and cleanroom facilities can be substantial. This often necessitates significant government funding, private sector investment, and collaborative efforts between academia and industry. Establishing the necessary infrastructure for large-scale production of nanomaterials and nanodevices is a continuous process.

Small and medium-sized enterprises (SMEs) face particular challenges in accessing these resources, highlighting the need for supportive policies and accessible funding mechanisms to ensure broad participation across the manufacturing ecosystem. The cost-benefit analysis must clearly demonstrate long-term returns to justify these upfront expenditures.

Workforce Development and Education

A critical challenge is the need for a highly skilled workforce capable of operating advanced nanotechnology equipment and understanding the complexities of nanoscale engineering. This requires significant investment in STEM education, vocational training programs, and continuous professional development for existing workers.

- Specialized Skills: Training programs must focus on areas such as nanofabrication, materials characterization, and computational modeling at the nanoscale.

- Interdisciplinary Expertise: Nanotechnology often requires collaboration between physicists, chemists, engineers, and biologists, necessitating interdisciplinary educational approaches.

- Safety Protocols: Ensuring workers are trained in the safe handling and disposal of nanomaterials is paramount, given potential health and environmental concerns.

Bridging the skills gap is essential for the US to maintain its competitive edge in advanced manufacturing. Universities, community colleges, and industry partners are increasingly collaborating to develop curricula that meet these evolving demands.

Regulatory and Ethical Considerations

As nanotechnology advances, so too do the questions surrounding its safety, environmental impact, and ethical implications. Developing clear, science-based regulatory frameworks is crucial to ensure public trust and responsible innovation. Agencies like the EPA and FDA are actively researching and establishing guidelines for the safe production and use of nanomaterials.

Open dialogue and public engagement are vital to address concerns and build confidence in nanotechnology’s benefits. Proactive measures in risk assessment and management are key to fostering a supportive environment for innovation while safeguarding public health and the environment.

Despite these challenges, the opportunities for economic growth, job creation, and technological leadership that nanotechnology presents are compelling. Strategic investments, robust educational initiatives, and thoughtful regulatory approaches will be critical for the US to fully harness this transformative technology.

Advancements in Nanofabrication Techniques

The ability to precisely build structures at the nanoscale is fundamental to unlocking nanotechnology’s full potential. Over the past few decades, significant advancements in nanofabrication techniques have transformed what was once theoretical into practical manufacturing processes. These techniques allow for the controlled assembly and creation of nanomaterials and devices with unprecedented accuracy.

The US has been a leader in developing and refining these sophisticated methods, which are crucial for producing everything from advanced semiconductors to novel medical devices. Continued innovation in this area is vital for maintaining a competitive edge in global high-tech manufacturing.

Top-Down and Bottom-Up Approaches

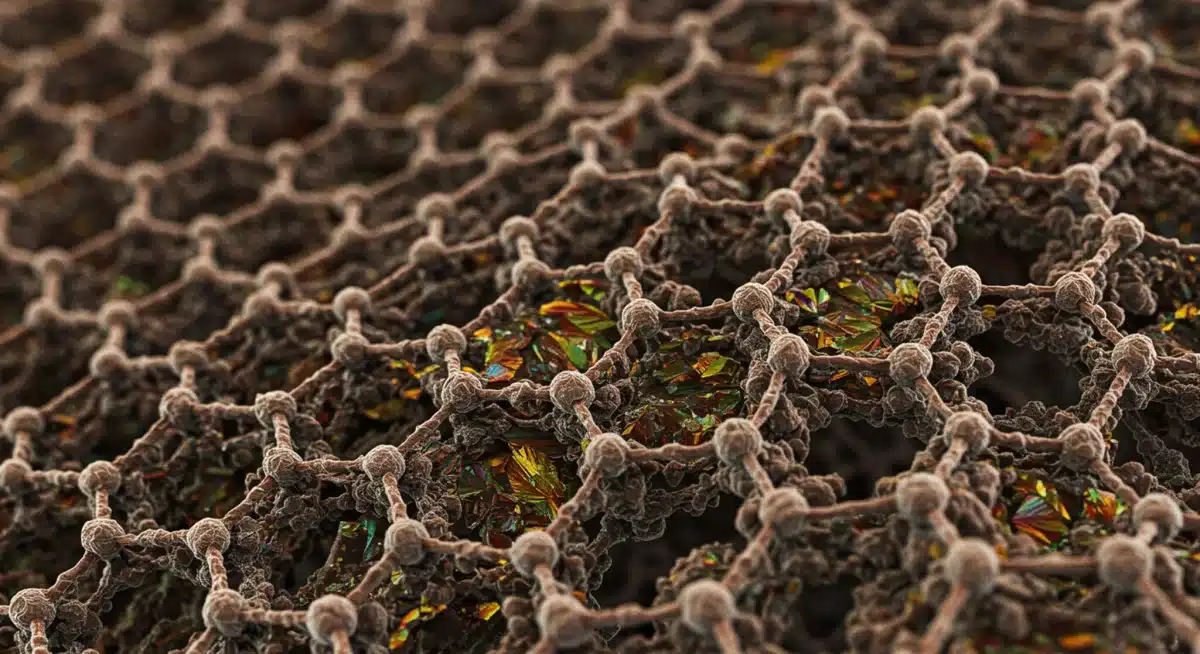

Nanofabrication generally falls into two main categories: top-down and bottom-up. Top-down methods involve starting with larger materials and scaling them down to nanoscale dimensions, often using techniques similar to those employed in microelectronics. Bottom-up approaches, conversely, involve assembling materials atom by atom or molecule by molecule, building structures from the ground up.

- Lithography: A cornerstone of top-down fabrication, various forms of lithography (e.g., photolithography, electron beam lithography) enable the patterning of materials at resolutions down to tens of nanometers, essential for integrated circuits.

- Self-Assembly: A powerful bottom-up technique where molecules or nanoparticles spontaneously organize into ordered structures due to their intrinsic properties, mimicking biological processes to create complex architectures.

- Atomic Layer Deposition (ALD): This precise method deposits thin films of material one atomic layer at a time, allowing for exceptional control over film thickness and composition, critical for advanced coatings and electronics.

These techniques, often used in combination, provide engineers with a diverse toolkit for creating a wide array of nanoscale devices and materials. The continuous refinement of these processes is directly contributing to the miniaturization and enhanced performance of electronic components and sensors.

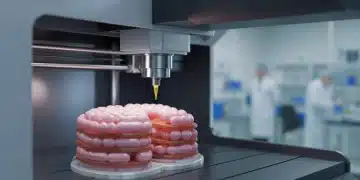

Emerging Nanofabrication Technologies

Beyond established methods, new nanofabrication techniques are constantly emerging, promising even greater precision, speed, and cost-effectiveness. These innovations are expanding the possibilities for nanotechnology in manufacturing, potentially enabling mass production of complex nanostructures.

For instance, advanced 3D nanofabrication methods are allowing for the creation of intricate, three-dimensional nanoscale architectures, which could revolutionize fields like photonics and metamaterials. These sophisticated manufacturing capabilities are pivotal for the US to maintain its leadership in high-tech industries.

The relentless pursuit of more efficient and precise nanofabrication techniques is a driving force behind the continued growth and impact of nanotechnology in US manufacturing. These advancements are not only enabling new products but also transforming the very processes by which they are made.

Economic Impact and Future Outlook for US Nanotechnology

The economic implications of nanotechnology advancements for US manufacturing are projected to be substantial, contributing to job creation, increased competitiveness, and the development of new industries. As nanoscale technologies mature, they are expected to drive significant economic growth and reshape the global industrial landscape.

Understanding this economic trajectory and anticipating future trends is crucial for policymakers, investors, and businesses looking to capitalize on the nanotechnology revolution within the United States.

Market Growth and Job Creation

The global market for nanotechnology is expanding rapidly, with significant portions attributed to applications in manufacturing. For the US, this translates into opportunities for job creation in research, development, and high-tech manufacturing sectors. These are often high-skill, high-wage jobs, contributing to a stronger domestic economy.

Investment in nanotechnology stimulates a ripple effect, fostering innovation in related fields and creating demand for new tools, materials, and services. This creates a robust ecosystem that supports sustained economic growth and technological advancement.

Strategic Importance and Global Competition

Nanotechnology is recognized as a strategic technology, vital for national security and economic prosperity. Countries worldwide are investing heavily in this field, making global competition fierce. For the US, continued leadership in nanotechnology is essential to maintain its competitive edge in advanced manufacturing and avoid reliance on foreign suppliers for critical components.

Protecting intellectual property and fostering a strong innovation environment are key to ensuring that the economic benefits of US-developed nanotechnology remain within the country, strengthening domestic industries and national capabilities.

Future Trends and Emerging Applications

Looking ahead, nanotechnology is poised to deliver even more groundbreaking innovations. Expect to see continued advancements in:

- Sustainable Manufacturing: Nanomaterials can enable more energy-efficient processes, reduce waste, and facilitate the development of biodegradable products.

- Artificial Intelligence Integration: Combining AI with nanotechnology could lead to self-optimizing manufacturing systems and smart materials that adapt to their environment.

- Quantum Computing Components: Nanoscale engineering is critical for developing the next generation of quantum computing hardware, promising unprecedented computational power.

These emerging applications highlight the long-term potential of nanotechnology to fundamentally transform various aspects of life and industry. The US is strategically positioning itself to be a leader in these future frontiers.

The economic future of US manufacturing is inextricably linked to its ability to harness and innovate with nanotechnology. By addressing current challenges and strategically investing in future trends, the US can ensure sustained growth, create high-value jobs, and maintain its technological leadership on the global stage.

Environmental and Safety Considerations in Nanomanufacturing

As nanotechnology becomes more integrated into US manufacturing, it’s crucial to address the environmental and safety considerations associated with nanomaterials. While offering immense benefits, the unique properties of nanoparticles also raise questions about their potential impact on human health and ecosystems. Responsible development and deployment are paramount to ensuring sustainable innovation.

A proactive approach to understanding and mitigating risks is essential for building public trust and ensuring the long-term viability of nanomanufacturing in the United States.

Assessing Environmental Impact

The small size and high surface area of nanomaterials give them novel properties, but also mean they can behave differently in the environment compared to larger particles. Research is ongoing to understand their fate and transport in air, water, and soil, as well as their potential effects on various organisms.

- Ecotoxicity Studies: Investigations into how nanomaterials interact with and affect flora and fauna are critical for designing safer materials and processes.

- Lifecycle Assessment: Evaluating the environmental footprint of nanomaterials from production to disposal helps identify potential risks and promote sustainable practices.

- Waste Management: Developing safe and effective methods for handling and disposing of waste containing nanomaterials is crucial to prevent environmental contamination.

US regulatory bodies and research institutions are actively collaborating to develop comprehensive guidelines and standards for environmental protection in nanomanufacturing.

Worker Safety and Health

Protecting workers involved in the production and handling of nanomaterials is a top priority. Exposure routes, such as inhalation or skin contact, need to be carefully controlled. Engineering controls, personal protective equipment (PPE), and robust industrial hygiene practices are essential to minimize risks.

The unique characteristics of nanomaterials, such as their ability to penetrate biological barriers, necessitate thorough toxicological studies and the development of specific occupational safety standards. Continuous monitoring and research are vital to adapt safety protocols as new nanomaterials and applications emerge.

Responsible Innovation and Regulation

The principle of responsible innovation guides the development of nanotechnology in the US, emphasizing the need to consider societal and ethical implications alongside scientific and economic benefits. This includes transparent communication, public engagement, and adaptive regulatory frameworks that can evolve with scientific understanding.

Collaboration between industry, academia, government agencies, and civil society is key to fostering an environment where nanotechnology can thrive safely and sustainably, maximizing its benefits while minimizing potential harm to people and the planet.

By prioritizing environmental stewardship and worker safety, US nanomanufacturing can continue to innovate and grow responsibly, ensuring that the benefits of this transformative technology are realized without compromising future generations.

| Key Aspect | Brief Description |

|---|---|

| Precision Manufacturing | Enables control over materials at atomic scale, leading to superior product performance and miniaturization. |

| Materials Revolution | Creates advanced composites and smart coatings with enhanced strength, durability, and functionality. |

| Sectoral Impact | Transforms aerospace, automotive, and healthcare with lighter components, efficient batteries, and targeted drug delivery. |

| Economic Outlook | Drives job creation, global competitiveness, and new industries through sustained investment and innovation. |

Frequently Asked Questions About Nanotechnology in US Manufacturing

Nanotechnology primarily impacts US manufacturing by enabling the creation of materials and products with unprecedented precision and enhanced properties. This leads to lighter, stronger, and more efficient goods, fostering innovation across sectors like aerospace, automotive, and healthcare, thereby boosting global competitiveness.

Nanotechnology improves materials science by allowing manipulation at the atomic and molecular levels, leading to novel properties. This results in advanced composites that are stronger and lighter, and smart coatings with functionalities like self-cleaning or corrosion resistance, significantly extending material lifespan and performance.

Key challenges include high upfront research and development costs, the need for specialized infrastructure, and a skilled workforce. Additionally, navigating evolving regulatory frameworks and addressing potential environmental and health concerns are crucial for widespread and responsible adoption in US manufacturing.

Several US industries are significantly affected, including aerospace for lighter components, automotive for fuel efficiency and battery tech, and healthcare for targeted drug delivery and advanced diagnostics. Electronics, energy, and defense sectors also see profound transformations due to nanoscale innovations.

The future economic outlook is highly positive, projecting substantial growth, job creation, and increased global competitiveness. Nanotechnology is expected to drive new industries, foster sustainable manufacturing practices, and integrate with AI for self-optimizing systems, securing the US’s position as a technological leader.

Conclusion

The profound impact of nanotechnology on US manufacturing and materials science is undeniable and continues to accelerate. By offering unprecedented control over matter at its most fundamental level, nanoscale engineering is not merely enhancing existing products but creating entirely new possibilities across diverse sectors. From revolutionizing aerospace and automotive industries with lighter, stronger materials to transforming healthcare with precision diagnostics and targeted therapies, nanotechnology is a cornerstone of modern innovation. While challenges related to investment, workforce development, and regulation persist, the strategic opportunities for economic growth, job creation, and global leadership are immense. As the United States continues to invest in research, foster collaboration, and prioritize responsible development, nanotechnology will undoubtedly remain a critical driver for a more efficient, sustainable, and technologically advanced manufacturing future.