3D-Printed Homes: Solving the US Housing Shortage by 2026

3D-printed homes offer a transformative approach to addressing the severe housing shortage in the US by 2026, leveraging rapid construction and cost-efficiency to deliver accessible, sustainable, and affordable housing solutions nationwide.

The housing crisis in the United States is a complex challenge, impacting millions of Americans. However, a revolutionary technology is emerging that promises to reshape the construction landscape: 3D-printed homes housing shortage solutions. This innovative approach could provide a significant answer to the urgent need for affordable and accessible housing across the nation by 2026.

Understanding the US Housing Shortage Landscape

The current housing shortage in the United States is not merely a localized issue; it is a widespread crisis affecting both urban and rural communities. Years of underbuilding, coupled with increasing population and escalating material costs, have created an imbalance between housing supply and demand. This deficit has pushed homeownership out of reach for many and exacerbated rental affordability issues, leading to significant societal and economic repercussions.

Several factors contribute to this persistent shortage. Economic growth in key regions attracts more residents, but new housing construction often lags behind. Additionally, restrictive zoning laws in many areas limit the density and type of housing that can be built, further constraining supply. The cost of traditional construction, including labor, materials, and land, continues to rise, making it difficult for developers to build affordable units at scale. This confluence of challenges demands innovative solutions that can circumvent these traditional barriers.

Key Drivers of the Housing Crisis

- Insufficient New Construction: For decades, the pace of new home construction has not kept up with population growth and household formation, creating a cumulative deficit.

- Rising Material and Labor Costs: The price of lumber, steel, and other building materials, alongside a shortage of skilled construction labor, significantly drives up the cost of new homes.

- Restrictive Zoning Regulations: Many municipalities have zoning ordinances that favor single-family homes and limit multi-family developments, hindering higher-density, more affordable housing options.

- Aging Housing Stock: A substantial portion of existing homes are older, requiring significant maintenance or renovation, which can be prohibitive for lower-income families.

The implications of this shortage are far-reaching. It impacts economic mobility, educational opportunities, and overall quality of life. Families struggle to find safe, affordable places to live, leading to increased homelessness and housing insecurity. Addressing this crisis requires a multi-faceted approach, and 3D printing technology is emerging as a powerful tool in this effort, offering the potential to build faster, cheaper, and more sustainably.

The Dawn of 3D-Printed Home Technology

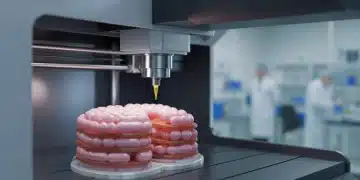

3D printing, or additive manufacturing, has transitioned from a niche technology for prototyping to a viable method for constructing entire buildings. In the context of housing, large-scale 3D printers extrude layers of concrete, polymer, or other composite materials to build walls and structural elements directly on-site. This method significantly reduces construction time and labor requirements, offering a promising alternative to conventional building practices.

The fundamental principle involves a digital design being fed into a robotic printer, which then precisely deposits material layer by layer. This automated process allows for complex geometries and designs that would be difficult or expensive to achieve with traditional methods. Early pioneers in this field have already demonstrated the feasibility of printing entire homes in a matter of days, rather than weeks or months.

The materials used in 3D printing often include specialized concrete mixtures that cure quickly and offer high structural integrity. Researchers are also exploring sustainable alternatives, such as recycled aggregates and bio-based materials, further enhancing the eco-friendly potential of this technology. The precision of 3D printing also minimizes waste, as materials are only used where needed, contributing to a more sustainable construction process.

How 3D Printing Transforms Construction

- Automated Precision: Digital blueprints guide the printer, ensuring high accuracy and consistency in construction, reducing human error.

- Reduced Construction Time: Walls and structural components can be printed in hours or days, dramatically cutting overall project timelines.

- Lower Labor Requirements: While skilled operators are needed, the automated nature of 3D printing reduces the reliance on a large, diverse construction crew, addressing labor shortages.

- Design Flexibility: The technology allows for innovative architectural designs, including curved walls and unique structural elements, without significant additional cost.

The rapid advancements in 3D printing technology, coupled with decreasing equipment costs, are making it an increasingly attractive option for addressing various construction challenges. Its ability to create durable, custom structures with efficiency and speed positions it as a disruptive force in the housing market, particularly for tackling the housing shortage.

Cost-Effectiveness and Speed: Key Advantages

One of the most compelling arguments for the widespread adoption of 3D-printed homes is their potential for significant cost reduction and accelerated construction timelines. Traditional homebuilding is notoriously expensive and time-consuming, driven by factors like labor wages, material procurement, and complex logistical coordination. 3D printing streamlines many of these processes, offering a more efficient paradigm.

By automating much of the construction of structural elements, 3D printing drastically cuts down on labor costs, which often constitute a large portion of a project’s budget. Furthermore, the precision of the printing process minimizes material waste, translating into further savings. The ability to construct a home in a matter of days or weeks, rather than months, also reduces overhead costs associated with extended project durations, such as financing interest and site management.

Consider the impact on developers and homebuyers alike. Developers can complete projects faster, turning over inventory more quickly and increasing their capacity to build more units. For homebuyers, this translates to more affordable purchase prices, making homeownership attainable for a broader segment of the population. The speed also means that communities in urgent need of housing can see solutions implemented much more rapidly.

Economic Benefits of 3D Printing in Housing

- Reduced Labor Costs: Automation minimizes the need for extensive manual labor, leading to substantial savings.

- Material Efficiency: Precise deposition of materials reduces waste, optimizing resource utilization and cutting down on raw material expenses.

- Faster Project Completion: Shorter construction cycles lead to lower financing costs and quicker returns on investment for developers.

- Scalability: The technology can be deployed to build multiple units efficiently, addressing demand at a larger scale.

These economic and temporal advantages make 3D-printed homes a powerful contender in the race to solve the US housing shortage. The capacity to build more homes for less money and in less time is precisely what is needed to bridge the current supply-demand gap, setting the stage for a more accessible housing market by 2026.

Sustainability and Environmental Impact

Beyond cost and speed, 3D-printed homes offer significant environmental benefits, aligning with the growing global emphasis on sustainable construction practices. Traditional construction is often resource-intensive, generating substantial waste and contributing to carbon emissions. 3D printing presents a greener alternative by inherently reducing material consumption and offering opportunities for using eco-friendly building materials.

The precise, additive nature of 3D printing means that materials are only deposited where structurally necessary, virtually eliminating waste commonly associated with cutting and shaping traditional building materials. This reduction in waste not only saves money but also lessens the environmental burden on landfills. Furthermore, the ability to print on-site reduces the need for extensive transportation of materials, lowering fuel consumption and associated emissions.

Many companies in the 3D printing construction sector are actively researching and incorporating sustainable materials into their processes. This includes using recycled concrete, local aggregates, and even bio-based mixtures, further enhancing the eco-credentials of 3D-printed structures. These homes can also be designed with optimized thermal performance, leading to lower energy consumption for heating and cooling once occupied.

Green Benefits of Additive Construction

- Minimized Material Waste: Precise printing reduces cut-offs and excess material, leading to less landfill waste.

- Reduced Transportation Emissions: On-site printing decreases the need to transport large volumes of pre-fabricated components, cutting down on fuel use.

- Use of Sustainable Materials: Research and development are focusing on incorporating recycled and environmentally friendly materials into printing mixtures.

- Improved Energy Efficiency: Designs can be optimized for insulation and passive heating/cooling, leading to lower operational energy demands.

The environmental advantages of 3D-printed homes make them not just a solution to the housing shortage, but also a step towards a more sustainable future for the construction industry. As the technology evolves, its positive impact on the planet is expected to grow, making it an even more attractive option for eco-conscious development.

Overcoming Challenges and Regulatory Hurdles

While the promise of 3D-printed homes is immense, their widespread adoption faces several challenges, particularly in the realm of regulatory approval and public perception. Building codes, which are often slow to adapt to new technologies, pose a significant hurdle. Many existing codes were developed with traditional construction methods in mind and do not explicitly cover or provide guidelines for 3D-printed structures.

Obtaining permits and ensuring compliance with local, state, and national building standards can be a complex and time-consuming process for developers utilizing this new technology. There’s a need for updated regulations that recognize the structural integrity and safety of 3D-printed materials and construction techniques. Collaboration between industry innovators, regulatory bodies, and policymakers is crucial to developing these new standards efficiently.

Public perception is another factor. While many are intrigued by the novelty, some potential homebuyers may harbor skepticism about the durability, longevity, or resale value of a 3D-printed home. Education and successful demonstration projects are vital to building trust and acceptance within the market. Showcasing the quality, customization, and aesthetic appeal of these homes will be key to shifting perceptions.

Key Obstacles to Broader Adoption

- Outdated Building Codes: Current regulations often lack specific provisions for 3D-printed construction, complicating approval processes.

- Public Acceptance and Education: Overcoming skepticism about new construction methods requires robust public awareness campaigns and successful case studies.

- Financing and Insurance: Lenders and insurance providers may be hesitant with novel construction types, potentially impacting accessibility for buyers.

- Skilled Workforce Development: While reducing traditional labor, 3D printing requires a new set of skills for operating and maintaining the advanced machinery.

Despite these challenges, progress is being made. Several pilot projects have successfully navigated regulatory pathways, and industry groups are actively working with government agencies to streamline approval processes. As more 3D-printed homes are built and inhabited, and their long-term performance is demonstrated, these hurdles are expected to diminish, paving the way for broader integration into the US housing market.

The Future Outlook: 3D-Printed Homes by 2026

Looking ahead to 2026, the trajectory for 3D-printed homes in the US is one of accelerating growth and increasing integration into mainstream housing solutions. The foundational work in technology development, material science, and early pilot projects is already establishing a strong base. By 2026, we anticipate a significant increase in the number of 3D-printed communities and individual homes, particularly in regions most affected by the housing shortage.

Several factors will contribute to this expansion. Continued advancements in printer technology will lead to faster, more versatile, and more affordable machines. Material innovation will introduce even more sustainable and durable options, while also expanding the aesthetic possibilities. Crucially, as more homes are successfully printed and occupied, regulatory bodies will likely accelerate the development of comprehensive building codes, making the approval process smoother and more predictable.

The economic pressures of the housing crisis will also act as a powerful catalyst. As traditional construction costs continue to climb, the cost-effectiveness of 3D printing will become an undeniable advantage for developers seeking to provide affordable housing. This will attract more investment into the sector, further driving innovation and scaling capabilities. Partnerships between technology companies, developers, and government agencies will be key to realizing this potential.

Projected Impact and Milestones by 2026

- Increased Production Capacity: Multiple companies will scale up their operations, capable of printing hundreds of homes annually.

- Broader Geographic Reach: 3D-printed homes will move beyond pilot projects to become established housing options in various states and regions.

- Enhanced Design and Customization: Greater flexibility in architectural styles and interior layouts will appeal to a wider range of buyers.

- Regulatory Harmonization: More states and municipalities will adopt specific building codes for 3D-printed construction, simplifying the permitting process.

By 2026, 3D-printed homes are poised to move from a novel concept to a tangible, impactful solution for the US housing shortage. Their ability to deliver affordable, sustainable, and rapidly constructed housing will not only help bridge the current supply gap but also redefine what is possible in the construction industry, fostering a new era of innovation and accessibility.

Impact on Affordable Housing Initiatives

The potential for 3D-printed homes to significantly impact affordable housing initiatives cannot be overstated. The core advantages of reduced cost and speed of construction directly address the most critical barriers to providing housing for low and middle-income families. Traditional affordable housing projects often struggle with funding gaps and lengthy development timelines, exacerbating the very problem they aim to solve.

By dramatically lowering per-unit construction costs, 3D printing allows developers, non-profits, and government programs to build more homes with existing budgets. This increase in supply directly targets the affordability crisis, making homeownership or quality rental units accessible to a larger segment of the population. Furthermore, the speed of construction means that housing solutions can be deployed much faster in communities facing urgent needs, such as those recovering from natural disasters or experiencing rapid population growth.

Consider the implications for communities struggling with homelessness. Rapidly deployable 3D-printed homes can offer quick, dignified, and permanent housing solutions, moving individuals and families out of temporary shelters or off the streets more efficiently. Non-profit organizations are already exploring these applications, recognizing the transformative potential of the technology to fulfill their missions more effectively.

How 3D Printing Boosts Affordability

- Lower Construction Costs: Direct savings on labor and materials translate into more affordable purchase prices for consumers.

- Increased Housing Supply: Faster construction allows for the production of more units, easing market pressure and driving down prices.

- Reduced Development Timelines: Quicker project completion means less time for costs to escalate, keeping prices stable.

- Innovative Funding Models: The efficiency and cost-effectiveness may attract new forms of investment and philanthropic support for affordable housing.

The alignment of 3D printing technology with the goals of affordable housing initiatives creates a powerful synergy. By 2026, it is highly probable that 3D-printed homes will be a cornerstone of many affordable housing strategies across the US, providing tangible solutions to a crisis that has long plagued the nation and offering a pathway to stable, secure housing for countless individuals and families.

| Key Aspect | Description |

|---|---|

| Housing Shortage | Persistent deficit in US housing supply due to underbuilding and rising costs. |

| 3D Printing Tech | Automated extrusion of materials for rapid, precise home construction. |

| Cost & Speed Benefits | Significant reductions in labor, material waste, and project timelines. |

| Future Outlook | Projected widespread adoption and regulatory adaptation by 2026. |

Frequently Asked Questions About 3D-Printed Homes

Many 3D-printed homes can have their structural walls completed in as little as 24 to 72 hours, depending on the design complexity and printer size. The entire construction process, including finishes, typically takes a few weeks, significantly faster than traditional building methods.

Yes, 3D-printed homes are designed to be highly durable and safe. They often use reinforced concrete or other robust composite materials that meet or exceed conventional building standards. Engineers rigorously test these structures for load-bearing capacity, seismic resistance, and weather resilience.

Cost savings can vary, but estimates suggest 3D-printed homes can be 10% to 30% cheaper than traditionally built homes of comparable size. This reduction primarily stems from lower labor costs, minimized material waste, and faster construction timelines, making them a more affordable option.

Absolutely. One of the significant advantages of 3D printing in construction is its design flexibility. Architects can create unique and complex geometries, curved walls, and custom layouts that would be cost-prohibitive with traditional methods, offering extensive customization options to homeowners.

Currently, regulations for 3D-printed homes are evolving. Some states and municipalities are developing specific codes, while others adapt existing international building codes. Industry groups are actively collaborating with regulatory bodies to establish standardized guidelines that ensure safety and facilitate broader adoption.

Conclusion

The US housing shortage is a formidable challenge, but the emergence of 3D-printed homes offers a powerful and innovative pathway towards a solution. By combining cost-effectiveness, rapid construction, and environmental sustainability, this technology is poised to revolutionize the residential construction sector. While challenges in regulation and public perception remain, the momentum behind 3D printing in housing is undeniable. By 2026, we can realistically expect to see a significant increase in the presence of 3D-printed communities, providing much-needed affordable and accessible housing options across the nation and fundamentally transforming the landscape of homebuilding for the better.